2024-2025 (Salman Oil Platform)

Successful Old Servers Upgrade and Renovation Project for SALMAN OIL PLATFORM.

We have successfully implemented a new Allen-Bradley Interface system at the SALMAN OIL platform! This project not only enhances operational efficiency but also significantly improves user experience by facilitating seamless communication with 28 PLCs. This advancement empowers operators to monitor and control processes more effectively, ensuring a safer and more efficient working environment.

Key Highlights:

Phased Rollout: We adopted a structured deployment strategy, ensuring minimal disruption during the transition.

Parallel Operation: The new Redundant Servers ran alongside the existing system for a year, allowing us to validate reliability and build user confidence before the full switch.

User Training: Comprehensive training sessions were conducted, utilizing detailed manuals and graphics.

Continuous Support: A robust support framework is now in place to assist users and ensure smooth operation.

This implementation marks a significant step forward in my commitment to leveraging technology for enhanced safety and efficiency. A big thank you to everyone involved for their hard work and dedication!

Looking forward to the continued success and future enhancements!

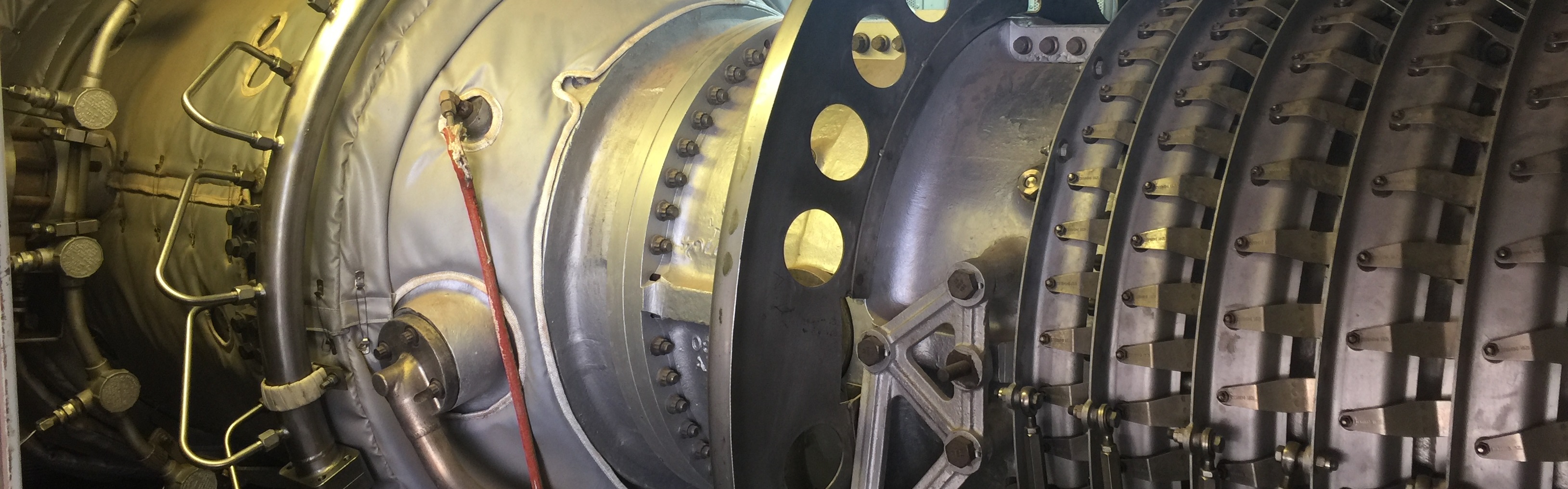

2023-2024 (SIRRI Island Power Plant)

Working on a major upgrade project at “Sirri Island” power plant. Replaced the old control system of a Siemens SGT200 gas turbine with a new Siemens 400 series system and PCS7 V9 software. This project, executed for NIOC, significantly enhanced the plant’s efficiency and reliability

2020-2022 (Resin Production Factory)

Completed a complex rebuild project at a chemical plant following a catastrophic control room fire. Successfully reprogrammed 9 SIEMENS S7-416 PLCs, designed and implemented a new monitoring system, and configured industrial servers and switches all in a PCS7 multi-project. This project highlights my expertise in PLC programming, industrial networking, and system recovery.

2017 (NISOC)

Overcoming technical challenges, We successfully upgraded the control system of a gas turbine at Aghajari (National Iranian South Oilfields Company) . By integrating a Siemens 400 series system and Shinkawa vibration monitoring, we optimized the Turbo-Compressor’s performance and ensured safe operations.

2016 (Rag-Sefid Turbo Pumps)

Successfully Revamped control and instrument systems of 3 trains ” Solar Centaur ” turbojet gas turbine successfully. using Siemens CPUs (PCS7 Software) for Control the sequence of the Turbines next to HIMA CPUs (Elop ll Software) for Control ESD & F&G, led to a smooth and reliable action in the process.

2014-2016 (Resin Production Factory)

Served as Technical Supervisor of the automation and instrumentation department for setting up two solid and liquid resin production lines.

Collaborated with Italy’s “Progecta” and Germany’s “Zeppelin” companies.

4 Independent process control systems, Siemens S7-414.